Originally posted by xviper

View Post

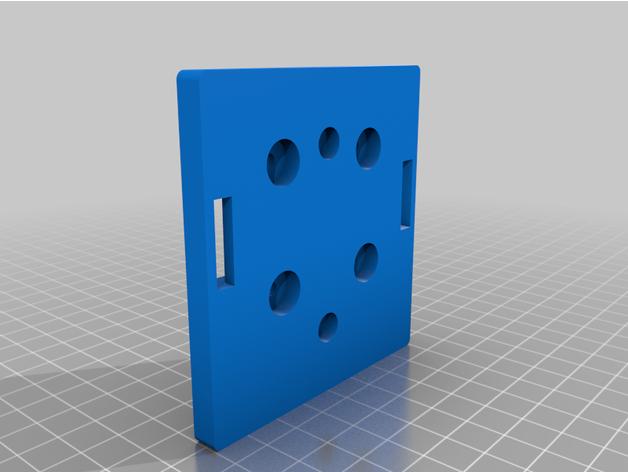

Anyways, here's a design that should make the front retract and housing pretty much tank-spec. Im not yet convinced it's needed but saw some folk on the Motion FB page reporting breakages in this area from tough landings.

If my flying season for this plane wasn't over, I'd do it just to see for myself. But even with what you got so far, there may be an answer looming close by.

If my flying season for this plane wasn't over, I'd do it just to see for myself. But even with what you got so far, there may be an answer looming close by.

Comment