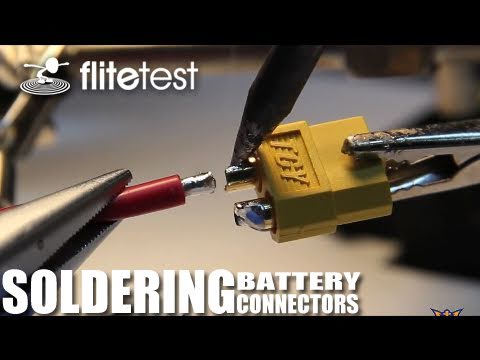

Hi. I'm just not a solder guy.

I'm open to help on how to solder effectively.AND/OR

my question is this. are there other ways to connect wires to lengthen esc' s etc.

that won't vibrate Loose. ???

I'm open to help on how to solder effectively.AND/OR

my question is this. are there other ways to connect wires to lengthen esc' s etc.

that won't vibrate Loose. ???

.png)

Comment