Im trying to repair some minor foam dents and dings in my Freewing f16 so i bought the beacon foam filler thinking it would be perfect because of it being light weight and sand able but NEGATIVE. Not sure if im doing something wrong but i applied it to the plane and its been about a day now and its sort of dry but if i put slight pressure on it it feels like hardened gum almost. and is pretty much impossible to sand. just rolls up. Maybe i got a bad batch of this stuff? any input would be much appreciated. i tried searching google for other people having this issue but couldn't find any solutions, THANKS in advanced!

Announcement

Collapse

No announcement yet.

Beacon Foam Filler help

Collapse

X

-

hey thanks for the input, yea sucks cause it was $10. going to get ahold of MRC and see what i can do about it. ill try that hobbico filler and hopefully have better results.Originally posted by RCjetdude View PostMy first tub of it was great. Dried well and was easy to sand. My second tub was not the same. More like what you are describing. I have since started using Hobbico HobbyLite balsa filler instead.

Comment

-

is this the one you use?? there are two different ones, both look identical though. think the only difference is this one is white?Originally posted by RCjetdude View PostMy first tub of it was great. Dried well and was easy to sand. My second tub was not the same. More like what you are describing. I have since started using Hobbico HobbyLite balsa filler instead.

Comment

-

Warbird Charlie

HSD Skyraider FlightLine OV-10 FMS 1400: P-40B, P-51, F4U, F6F, T-28, P-40E, Pitts, 1700 F4U & F7F, FOX glider Freewing A-6, T-33, P-51 Dynam ME-262, Waco TF Giant P-47; ESM F7F-3 LX PBJ-1 EFL CZ T-28, C-150, 1500 P-51 & FW-190

Comment

-

I just recently bought some of the Beacon Foam filler and had the same issues as you did 210foo. I thought I also had a bad batch of the stuff.

I have been recently experimenting with fillers and patch repair products and her are my findings so far:

Hobbico Hobbylite balsa filler: { tan or white colors }

PROs: It dries fast ; has the best sanding qualities ; does not stick to your fingers as much as the other fillers tend to do so

CONs: It is very brittle and chips or breaks very easy when sanding ; it needs to be forced on / in to the surface for good adhesion ; it does not like to adhere to itself making layered patch work difficult

Red Devil lite drywall spackle from Ace Hardware:

PROs: dries fairly quickly ; has the second best sanding qualities but will roll up on you if you use to much force in your sanding efforts ; has the best surface adhesion of all the fillers I have tested when properly mixed

it is not as brittle as Hobbylite balsa filler and It can be layered upon itself for patch work build ups with good results

CONs: It is very sticky on the fingers and will get every where if you are not careful ; For best results, it is good to let sit over night to fully cure

Testor's Contour Putty:

PROs: It has decent sanding qualities but you have to be careful when sanding against foam ; it works great for filling small and light scratches in foam as it can be squeegeed in place and require minimal sanding to surface ; works very well in patching the chips and breaks that may occur while sanding the other fillers ; It is very strong and durable

CONs: It has mediocre adhesion qualities on soft flexible material like foam and will lift easily if you are not careful ; it is much harder than the other fillers and foam for that matter so care must be taken when sanding

Squadron Signal Filler Putty: { green or white colors }

PROs: same as Testor's Contour Putty ; it has better surface adhesion than the Testor's putty

CONs: it is more sticky on the fingers than the Testor's putty and can be easily smeared around on the surface if not careful ; it is much harder than the other fillers and foam for that matter so care must be taken when sanding

Comment

-

The Squadron Green putty is more of a spot putty and the solvents in it may soften bare EPO so I only apply it very thinly and on previously filled or painted surfaces. It tends to shrink a lot. If you thin the Hobbylite Balsa filler with a little bit of water it covers itself well and adheres good. I put it on with an artists trowel. If you check out The RC Geeks Youtube channel he has a complete tutorial on refinishing a foam warbird (P-51) which is very helpful.

Comment

-

I'm concerned about this problem, because I use Beacon Foam-Filler myself (extensively) and I also sell it in my business. Of course MRC sells it as well. I have been using it for years and I find it to be one of the best products out there. It goes on very smooth with a knife-edge (and can be smoothed further with a little extra water) and sands cleanly. So I'm a strong advocate and a little defensive I guess (but I REALLY like this product). It can be used on foam, balsa, and even paper.

Reading the original issue (first post) I think that the problem may be that it may have been applied too thickly.

This the key thing to understand. The product needs to be applied in thin layers in order for it to dry, and thin layers dry very quickly. And it must be completely dry in order to sand.... if its applied in a thick blob it may take days or even weeks to cure all the way through and my guess is that's what happened in this case. It's not going to sand properly if its not completely dry.

I checked with the product manager at Beacon, his name is Pete and a terrific guy that I know personally. Foam-Filler's formula has NOT been changed.

He said "when something works this well we don't change it". If you'd like to talk to him call 914-699-3400 and ask for him. (he encouraged me to post his info)Marc flies FW & FL: AL37, MiG-29, T45,F4, A4, A10, F104 70 and 90, P38, Dauntless SBD, Corsair, B17, B24, B26 & P61, Lipp.P19, ME262, Komets, Vampire, SeaVixen, FMS Tigercat, FOX Glider & Radian XL.

Rabid Models foamies, including my 8' B17 & 9' B36... and my Mud Ducks! www.rabidmodels.com

- Likes 1

Comment

-

I totally agree......;)Originally posted by themudduck View PostI'm concerned about this problem, because I use Beacon Foam-Filler myself (extensively) and I also sell it in my business. Of course MRC sells it as well. I have been using it for years and I find it to be one of the best products out there. It goes on very smooth with a knife-edge (and can be smoothed further with a little extra water) and sands cleanly. So I'm a strong advocate and a little defensive I guess (but I REALLY like this product). It can be used on foam, balsa, and even paper.

Reading the original issue (first post) I think that the problem may be that it may have been applied too thickly.

This the key thing to understand. The product needs to be applied in thin layers in order for it to dry, and thin layers dry very quickly. And it must be completely dry in order to sand.... if its applied in a thick blob it may take days or even weeks to cure all the way through and my guess is that's what happened in this case. It's not going to sand properly if its not completely dry.

I checked with the product manager at Beacon, his name is Pete and a terrific guy that I know personally. Foam-Filler's formula has NOT been changed.

He said "when something works this well we don't change it". If you'd like to talk to him call 914-699-3400 and ask for him. (he encouraged me to post his info)

Any filler product if gobbed on heavy enough takes exponentially more time to cure.

In some cases it may never cure because the curing agent of air can never reach the deeper/thicker areas.

These type of wood filler products are not cured by a chemical heat reaction like epoxy or bondo

It would be nice if products instructed on application thickness vs cure times but they don't because there are to many variables outside of their control such as humidity and temp levels.

As MD mentioned, application thickness needs to be in moderation.Warbird Charlie

HSD Skyraider FlightLine OV-10 FMS 1400: P-40B, P-51, F4U, F6F, T-28, P-40E, Pitts, 1700 F4U & F7F, FOX glider Freewing A-6, T-33, P-51 Dynam ME-262, Waco TF Giant P-47; ESM F7F-3 LX PBJ-1 EFL CZ T-28, C-150, 1500 P-51 & FW-190

Comment

-

I saw a very noticeable difference in the consistency of the first container of it I got and the second. I used the first container to fill in the leading edges on my Blue Angels A-4 where the gun mount was. It was very thick, dried great and sanded as it always had. The second container I got was not the same. I don't know it if has a shelf life or if it was not mixed enough but I will experiment with it some more to see if I can figure it out.

Comment

-

Steve..........if unused for some time the consistency/pastiness does get a little thicker which requires a thorough stirring.

Sometimes adding a drizzle of water to thin it out helps too.Warbird Charlie

HSD Skyraider FlightLine OV-10 FMS 1400: P-40B, P-51, F4U, F6F, T-28, P-40E, Pitts, 1700 F4U & F7F, FOX glider Freewing A-6, T-33, P-51 Dynam ME-262, Waco TF Giant P-47; ESM F7F-3 LX PBJ-1 EFL CZ T-28, C-150, 1500 P-51 & FW-190

Comment

-

hey i 100 percent agree with what your saying and thats actually what i kind of thought my issue was after messing around with the stuff and reading into it but there were also spots where i put little coats of the filler and still had the same results. so i got a scratch piece of foam did test samples of different thickness and still had the same results.Originally posted by themudduck View PostI'm concerned about this problem, because I use Beacon Foam-Filler myself (extensively) and I also sell it in my business. Of course MRC sells it as well. I have been using it for years and I find it to be one of the best products out there. It goes on very smooth with a knife-edge (and can be smoothed further with a little extra water) and sands cleanly. So I'm a strong advocate and a little defensive I guess (but I REALLY like this product). It can be used on foam, balsa, and even paper.

Reading the original issue (first post) I think that the problem may be that it may have been applied too thickly.

This the key thing to understand. The product needs to be applied in thin layers in order for it to dry, and thin layers dry very quickly. And it must be completely dry in order to sand.... if its applied in a thick blob it may take days or even weeks to cure all the way through and my guess is that's what happened in this case. It's not going to sand properly if its not completely dry.

I checked with the product manager at Beacon, his name is Pete and a terrific guy that I know personally. Foam-Filler's formula has NOT been changed.

He said "when something works this well we don't change it". If you'd like to talk to him call 914-699-3400 and ask for him. (he encouraged me to post his info)

Comment

-

210foo - I guess taking into account what everyone's saying, maybe its possible that you got a bad one. I just wanted to make sure everyone knows that the formula has not been changed. I can't imagine how one container would be different - but apparently you found the one that is! I've probably gone through a dozen cans over the past few years and never had a problem. If the stuff towards the bottom dries out I just add a little water and stir it up really well and it works fine (but only add a little bit of water).

What OV10 (Charlie) said. Maybe it just needs to be mixed well.Marc flies FW & FL: AL37, MiG-29, T45,F4, A4, A10, F104 70 and 90, P38, Dauntless SBD, Corsair, B17, B24, B26 & P61, Lipp.P19, ME262, Komets, Vampire, SeaVixen, FMS Tigercat, FOX Glider & Radian XL.

Rabid Models foamies, including my 8' B17 & 9' B36... and my Mud Ducks! www.rabidmodels.com

Comment

-

Yea I noticed the top of the filler was a little dry so I mixed it real good. Also what grit sand paper are you using?Originally posted by themudduck View Post210foo - I guess taking into account what everyone's saying, maybe its possible that you got a bad one. I just wanted to make sure everyone knows that the formula has not been changed. I can't imagine how one container would be different - but apparently you found the one that is! I've probably gone through a dozen cans over the past few years and never had a problem. If the stuff towards the bottom dries out I just add a little water and stir it up really well and it works fine (but only add a little bit of water).

What OV10 (Charlie) said. Maybe it just needs to be mixed well.

Comment

-

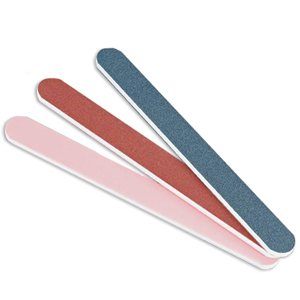

Generally I use 150 grit, and do a final polish with 320 before painting. I use these foam sanding sticks that I've been purchasing at the Toledo RC show for the past several years. I don't know who makes them.Originally posted by 210foo View Post

Yea I noticed the top of the filler was a little dry so I mixed it real good. Also what grit sand paper are you using?

Marc flies FW & FL: AL37, MiG-29, T45,F4, A4, A10, F104 70 and 90, P38, Dauntless SBD, Corsair, B17, B24, B26 & P61, Lipp.P19, ME262, Komets, Vampire, SeaVixen, FMS Tigercat, FOX Glider & Radian XL.

Marc flies FW & FL: AL37, MiG-29, T45,F4, A4, A10, F104 70 and 90, P38, Dauntless SBD, Corsair, B17, B24, B26 & P61, Lipp.P19, ME262, Komets, Vampire, SeaVixen, FMS Tigercat, FOX Glider & Radian XL.

Rabid Models foamies, including my 8' B17 & 9' B36... and my Mud Ducks! www.rabidmodels.com

Comment

Comment