As requested by Keilau, this is the full build and my amateurish approach to a Challenger 2, as used by the Scots Dragoon Guards. My previous thread was the abbreviated write up. This has all the failing, breakages, and general fu#* ups. A warts an all write up. I purchased a basic spec model, but with metal road wheels and tracks. I hope to move on having learnt a lot from building my Abrams. With this one I have not rushed in like I did with the Abrams, and have more of a plan.

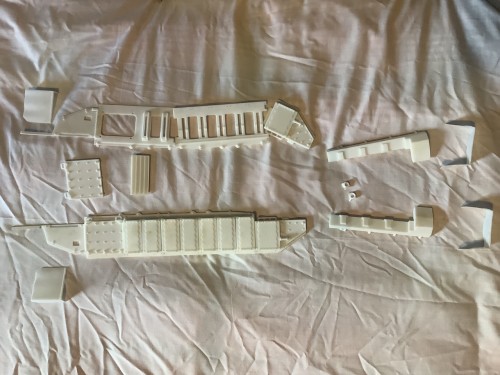

Anyway a couple of weeks ago a box came from DKLMRC, containing tracks, drive sprockets, idlers and the Chobham Armour. The tank was dismantled and the new tracks, idlers, and sprockets fitted.

First problem, the DKLM drive sprockets are too narrow, so used the original sprockets, which resulted in a very smooth drive.

Next I assembled on side of the add on armour, just for ****s and giggles and to see what it looked like.

A start has been made on the nose armour pack, which was glued into place and a pair of screws and nuts were used to represent the large nuts and bolts that hold the armour to the recovery points. Two self tappers were used to get a good glue bond. The nose armour required the detail removing from the front and a small amount of filling to fit.These will be filled later. JB Weld was used to attach the front armour. Please note, for our colonial cousins the correct spelling of the word armour. 🤣

While this was drying a start was made on the taillights. Slowly, slowly one at a time.

Again I hope to get it looking good from 3m away, .

.

Electronic wise, I think I am going to keep it simple, as I do not battle, unless my friends autistic son is around, I might just tell him we can not fight, as he kept beating me when I used the Challenger and he used my T72, and mainly just run for pleasure around the garden. I am thinking a 6.1 control, with a 360 turret, flashing and smoking gun, with recoil,and the bb mechanism removed. I will try to get working indicators and brake lights.

Anyway a couple of weeks ago a box came from DKLMRC, containing tracks, drive sprockets, idlers and the Chobham Armour. The tank was dismantled and the new tracks, idlers, and sprockets fitted.

First problem, the DKLM drive sprockets are too narrow, so used the original sprockets, which resulted in a very smooth drive.

Next I assembled on side of the add on armour, just for ****s and giggles and to see what it looked like.

A start has been made on the nose armour pack, which was glued into place and a pair of screws and nuts were used to represent the large nuts and bolts that hold the armour to the recovery points. Two self tappers were used to get a good glue bond. The nose armour required the detail removing from the front and a small amount of filling to fit.These will be filled later. JB Weld was used to attach the front armour. Please note, for our colonial cousins the correct spelling of the word armour. 🤣

While this was drying a start was made on the taillights. Slowly, slowly one at a time.

Again I hope to get it looking good from 3m away,

Electronic wise, I think I am going to keep it simple, as I do not battle, unless my friends autistic son is around, I might just tell him we can not fight, as he kept beating me when I used the Challenger and he used my T72, and mainly just run for pleasure around the garden. I am thinking a 6.1 control, with a 360 turret, flashing and smoking gun, with recoil,and the bb mechanism removed. I will try to get working indicators and brake lights.

Comment