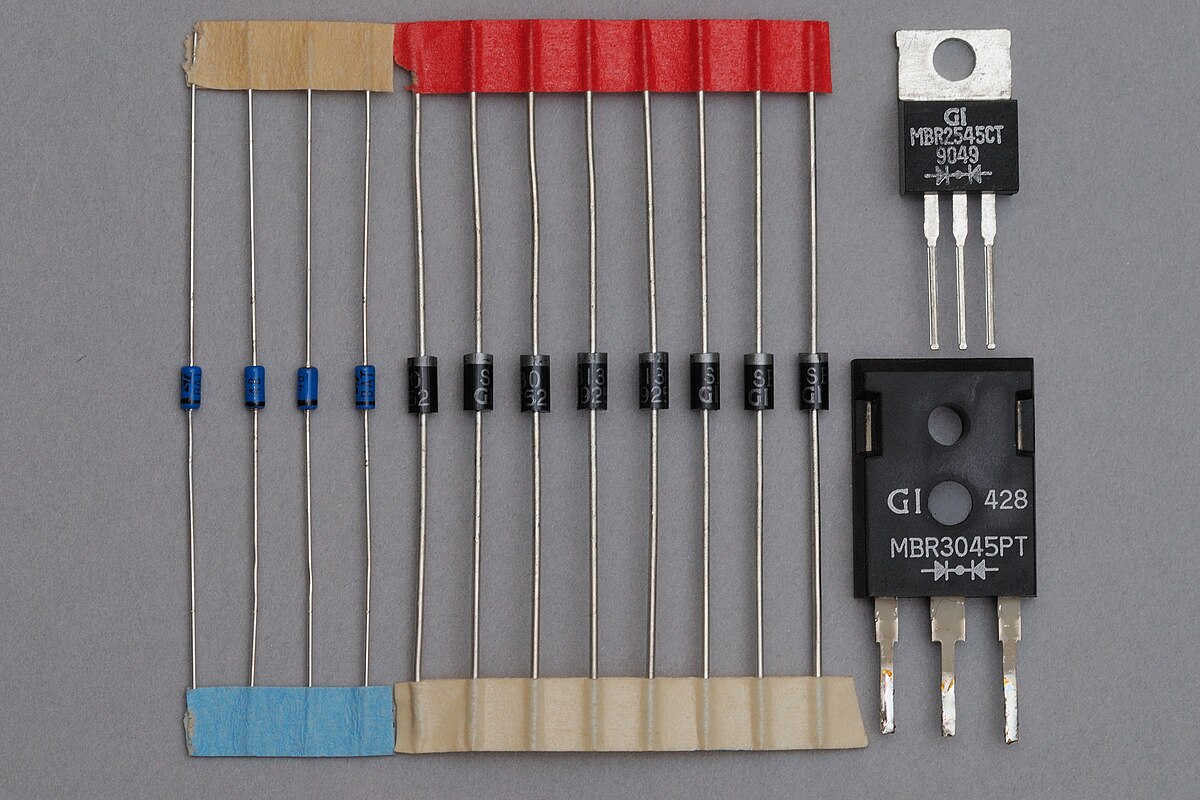

We used to use "Shotkey Diodes" on brushed motors to deal with the spikes.

But even high speed of a Shotkey is not fast enough for the high switching rate of a brushless ESC.

But even high speed of a Shotkey is not fast enough for the high switching rate of a brushless ESC.

Comment