Woody, glad you asked about the material. I didn't think acetone worked on PLA either. ;)

Announcement

Collapse

No announcement yet.

Official 3DP Thread

Collapse

X

-

I've been doing some non RC 3D printing too. (More non RC than for RC)

Samples below are a "Dice tower" to help ensure even loaded dice would roll randomly (D20 are notorious for being out of balance) and "minis" printed in white PLA then painted. Quarter, D20 (same one as on the Dice Tower is by the dragon) and SD cards for scale.

I mix my own colors for painting.2 PhotosFF gliders and rubber power since 1966, CL 1970-1990, RC since 1975.

current planes from 1/2 oz to 22 lbs

- Likes 3

Comment

-

I do. Here is a picture. Basically, it keeps out any drafts and helps increase the ambient temperature in the "chamber" to the mid/high-80s.

When I print with ABS, the cooling fan is disabled, but this does have a bit of a drawback. For any small sections, the sections can get a bit "melty" looking due to no cooling. To address this, I usually print parts in pairs or more. This allows a bit of time for the layer to cool before the next layer is extruded.1 Photo

- Likes 1

Comment

-

My plan for an enclosure is to use coroplast for the main walls and top. Just enough frame to hold the lightweight stuff together and allow hinging a section of plexi as the door.

Very cheap materials except the door.

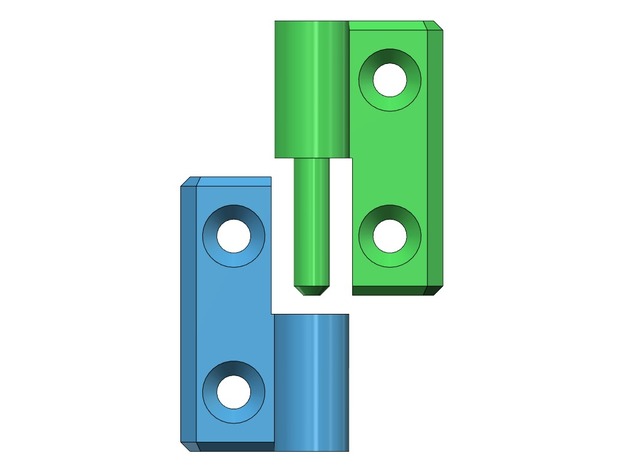

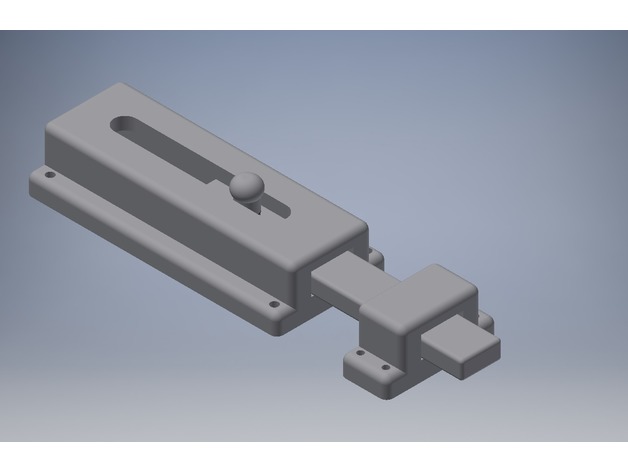

And I found you can 3D print the hinges and door latch.

A hinge to easily remove the door of the Anycubic 4MAX or DIY closed chamber. There are two STL-files, one with the needed spacer (4MAX) already attached (incl) and one with the spacer separated (sep). A closed door is not always better for printing and an opened door can be easily damaged. With these hinges you can remove and install the door in one second. The hinges are more then strong enough for their purpose. They are a little bigger in size then the original ones but they fit perfectly. The original screws can be used. A little smoothing/post-processing of the hinges can be necessary. Distance holes is 25 mm in both directions, thickness spacer is 4.5 mm. Happy hinging :) Ps. Apologies for the photo quality, photographing is not my greatest talent and black on black is hard to capture.

A hinge to easily remove the door of the Anycubic 4MAX or DIY closed chamber. There are two STL-files, one with the needed spacer (4MAX) already attached (incl) and one with the spacer separated (sep). A closed door is not always better for printing and an opened door can be easily damaged. With these hinges you can remove and install the door in one second. The hinges are more then strong enough for their purpose. They are a little bigger in size then the original ones but they fit perfectly. The original screws can be used. A little smoothing/post-processing of the hinges can be necessary. Distance holes is 25 mm in both directions, thickness spacer is 4.5 mm. Happy hinging :) Ps. Apologies for the photo quality, photographing is not my greatest talent and black on black is hard to capture.

This latch is printed in 4 parts and I have prepared Gcode for all the files but I have included the IPTs and STLs if you want to make modifications. The pin goes into the hole on the bar after you put in the main chassis. The smaller chassis can be positioned across the gap between the door, gate, etc and the wall, fence, etc in line with the main chassis to allow the latch to work. I have included an assembly picture to make putting it together easier. If you have any questions please do contact me.

This latch is printed in 4 parts and I have prepared Gcode for all the files but I have included the IPTs and STLs if you want to make modifications. The pin goes into the hole on the bar after you put in the main chassis. The smaller chassis can be positioned across the gap between the door, gate, etc and the wall, fence, etc in line with the main chassis to allow the latch to work. I have included an assembly picture to make putting it together easier. If you have any questions please do contact me.

Don't forget the enclosure DOES need air exchange with the room or air in from the room and ducted to exhaust outdoors. Its pretty easy to make an oven. The Kenner EZ bake just uses a 100 watt light bulb to bake cookies and small cakes. There's more watts of heat production in an Ender 3 than that.FF gliders and rubber power since 1966, CL 1970-1990, RC since 1975.

current planes from 1/2 oz to 22 lbs

Comment

-

RMBTX, I know I am delinquent in the work there with my F-4 build. So far all parts are good, though again, these are PLA. I hope I do not regret that. Like you, I had some super thin walls and thought I'd back those areas with CA and .6 fiberglass cloth. I will need to research all the component parts as I have none: EDF, motor, retracts etcetera. How's the PBY coming? Best, LBOriginally posted by rifleman_btx View PostLB, I did pick up the F86 as well so cant wait to see how yours works out

I solemnly swear to "over-celebrate" the smallest of victories.~Lucky B*st*rd~

You'll never be good at something unless you're willing to suck at it first.~Anonymous~

AMA#116446

Comment

-

LB, Funny you should ask, had to put that on hold because the Cessna went in and i have to reprint and replace a bunch of parts for it. And then i think im gonna go for the 64" Edge 540, then the PBY. After those are ironed out, i have the F86 myself. Man these printers given me the bug LOL

on a side note the prints coming off the new printer seem alot more fuller than the ones off the anet. Seems to be an even brighter white

- Likes 2

Comment

-

RMBTX, A difference in nozzle size or even firmware? Sounds like it's a good thing no matter. LOL Best, LBOriginally posted by rifleman_btx View PostLB, Funny you should ask, had to put that on hold because the Cessna went in and i have to reprint and replace a bunch of parts for it. And then i think im gonna go for the 64" Edge 540, then the PBY. After those are ironed out, i have the F86 myself. Man these printers given me the bug LOLon a side note the prints coming off the new printer seem alot more fuller than the ones off the anet. Seems to be an even brighter white

I solemnly swear to "over-celebrate" the smallest of victories.~Lucky B*st*rd~

You'll never be good at something unless you're willing to suck at it first.~Anonymous~

AMA#116446

Comment

-

That is my thought. Each time a upgrade to the latest firmware, the prints just get better and I know I'm not doing anything differently. LOLI'm just not that smart. Best, LBOriginally posted by rifleman_btx View PostIm thinking better firmware might be it, as they are both running .4mm nozzles.I solemnly swear to "over-celebrate" the smallest of victories.~Lucky B*st*rd~

You'll never be good at something unless you're willing to suck at it first.~Anonymous~

AMA#116446

- Likes 2

Comment

Comment