Originally posted by Aros.MotionRC

View Post

Announcement

Collapse

No announcement yet.

3d Printed Part Sets - Freewing F-4D Phantom II

Collapse

X

-

I printed in what my software calls spiral mode, which kept the print times down ( about a third of what a normal print was going to run.)Originally posted by Flash Jorden View PostLooks like you printed without supports, and it turned out well. I added lots of supports (missed adding some). We'll see how it goes.

Comment

-

I have a Cel RoboxOriginally posted by Gringotuerto View Post

What printer are you using that has 20um resolution? My printer claims 20um minimum layer height, but if I choose the "high detail" preset it defaults to 50um. If I manually change only the layer height to 20um, it prints much worse....looks like it is melting what it already printed, and just making a mess. Maybe I have to change many other things to avoid this. I tried messing with some of the other parameters (fan, etc. ) but I never found anything that prints better than the "high detail" default settings with 50um layer height.

Originally posted by Flash Jorden View PostQuick question.

What is MRC's stance/thoughts on guys printing these parts for a fee for others without printers? Not trying to start a flame war, just wondering.

They specifically ask you not to monetize the files in any way

Comment

-

This was my first time modeling a piece to print. Don't be too impressed... the detail on the outside of the nozzle is sheet styrene that I added. I just designed the basic shape but it did fit like I wanted it to.Originally posted by bbaumer View Post

Do you have 3d modeling experience? you did a nice job with those.

Comment

-

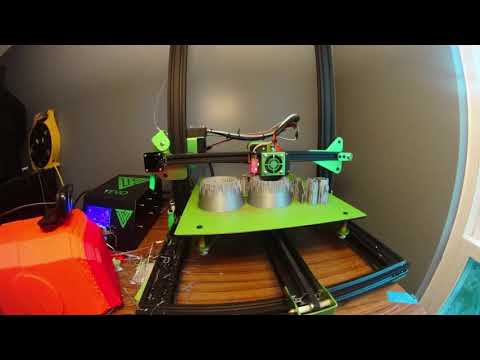

Here's my best shot at some cockpit panels. I'm coming to the conclusion it's going to be very difficult to recreate the quality you see in Motions pre-printed parts on any level of hobbyist 3D printer. I think I'll be able to get "good enough" level, but at the price of $20 or so the factory prints will be a bargain and will likely be the highest quality prints available. For those of you thinking of buying a printer, keep this in mind.

1 Photo

- Likes 1

Comment

-

Based upon my current printing attempts, I agree 100%Originally posted by bbaumer View PostHere's my best shot at some cockpit panels. I'm coming to the conclusion it's going to be very difficult to recreate the quality you see in Motions pre-printed parts on any level of hobbyist 3D printer. I think I'll be able to get "good enough" level, but at the price of $20 or so the factory prints will be a bargain and will likely be the highest quality prints available. For those of you thinking of buying a printer, keep this in mind.

bbaumer, what speed and other basic settings are you using, if you don't mind sharing?

I'm using Simplify 3D printing at .2mm layer height, 2 perimeters, 100% infill (not that it needs that much, 30-50% would probably work well), 210/60C temps, at 50mm/s.

Comment

-

Well, interestingly enough, my printer is a "plug and play" one. The software is called AutoMaker, and it is proprietary to the printer.Originally posted by Flash Jorden View Post

Based upon my current printing attempts, I agree 100%

bbaumer, what speed and other basic settings are you using, if you don't mind sharing?

I'm using Simplify 3D printing at .2mm layer height, 2 perimeters, 100% infill (not that it needs that much, 30-50% would probably work well), 210/60C temps, at 50mm/s.

I've got 3 basic levels of detail to select from with standard printing, or I can select a spiral mode. I've never dug into the custom settings much. Looking into it, the fine settings are

.10mm layer height 40% fill, 3 perimeters, speeds are .8mm/s on first layer, 25mm/s pretty typical elsewhere, i'm using a .3mm nozzle and printing with PLA

It also calculates all its own supports, you can see those in my earlier picture as the lattice work underneath parts

Temperatures are read from an EEProm on the spool, including bed and head temps

- Likes 1

Comment

Comment