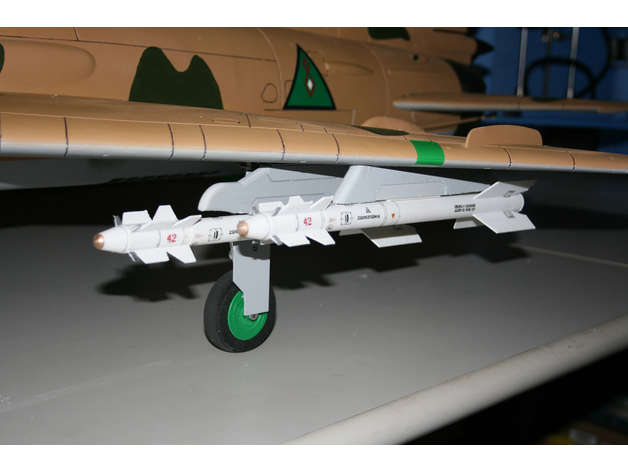

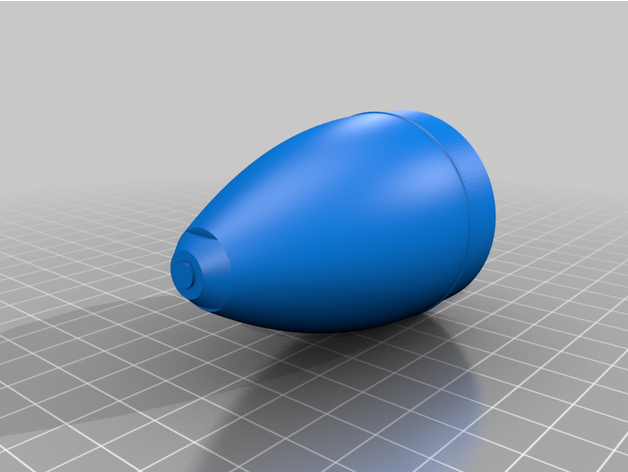

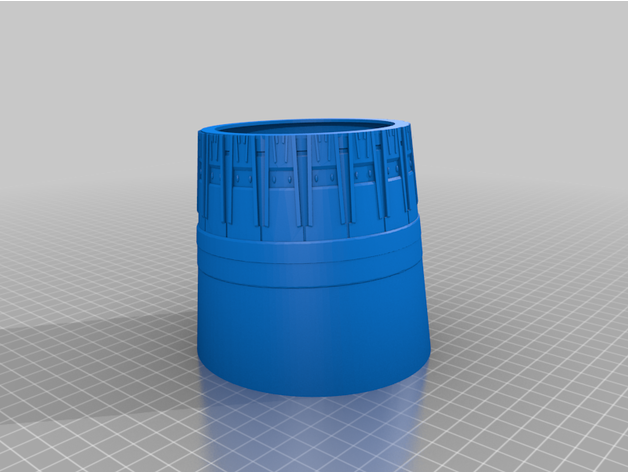

[QUOTE=Radar-Guy;n290242The files for the nozzle are available for a fee on cults 3d.In addition, I've uploaded a file for the ventral air scoop that was omitted by the designers of the model. This one is for free.[/QUOTE]

RG, Absolutely phenomenal designs. Bravo Zulu, Sir and thank you. Best, LB

RG, Absolutely phenomenal designs. Bravo Zulu, Sir and thank you. Best, LB

Comment